The Future of Electronics Manufacturing: Cutting-Edge Innovations

Electronics are part and parcel of modern life and can be found everywhere from devices in our pockets and on our wrists to powerful gaming computers and advanced medical equipment. The field of electronics manufacturing is always advancing and is currently in a period of transformation – transformation driven by advances in materials, processes and automation. Many of these advances have been enabled by recent developments in electronic manufacturing, creating a virtuous circle that’s powering the current pace of developments. Here’s a look at some of the most exciting developments shaping the future of this industry.

Advanced Materials and Components

Two-dimensional materials such as graphene, which consist of a single layer of atoms, are revolutionizing the electronics sector thanks to their exceptional electrical, thermal and mechanical properties. It is becoming increasingly practical to incorporate graphene into production processes, creating possibilities for flexible and transparent electronics, high-speed transistors and increasingly efficient power storage devices.

The ever-present goal of electronic manufacturing is to make devices and components smaller – this makes them more efficient and improves performance. Nanotechnology continues to advance and enhance this area of development. Nanowires, nanotubes and quantum dots can now be integrated into individual components like transistors or larger parts like displays.

Flexible and Wearable Electronics

Flexible Printed Circuits (FPC) are well-established in specific manufacturing applications but the latest FPCs are more durable, versatile and cost-effective than ever. They can now be relied on to flex during use, not just during production, which is key to creating wearable devices and flexible displays which can fold or roll up.

Organic semiconductors are made from carbon-based molecules – they are an old idea that is now coming to the fore thanks to improvements in their efficiency and fabrication techniques. Organic components have advantages of flexibility, low weight and – potentially – lower production costs. They are already used for Organic Light Emitting Diodes in high-resolution thin displays for phones, televisions and lighting units, and they have big promise for providing biodegradable, sustainable and biocompatible components.

Manufacturing Developments

As in many fields, 3D printing is the big frontier that’s advancing here. It has become increasingly sophisticated and precise. For electronics, micro 3D printing allows for the direct printing of circuits and components. Parts can be rapidly prototypes or custom-made for specific purposes. The latest 3D printing processes allow for multi-material printing, conductive inks and other options which open up new avenues for creativity and design.

Numerous tech developments come together to deliver new smart manufacturing processes – machine learning, artificial intelligence and the Internet of Things can combine to create production lines that are not only automated but ‘smart’. They can include features like predictive maintenance, real-time monitoring, adaptive control and automatic AI-driven quality control.

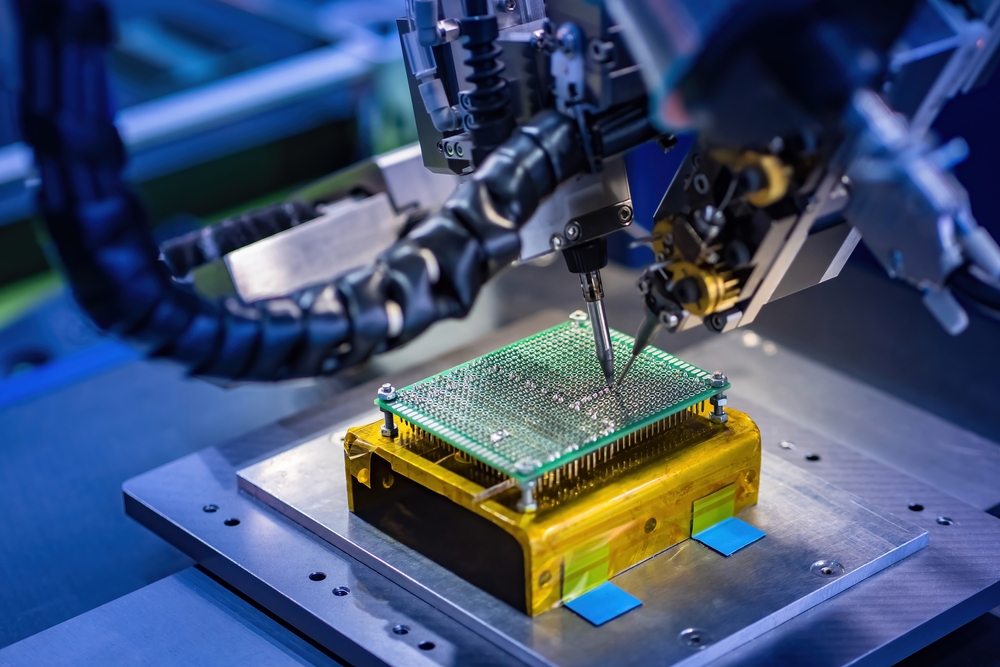

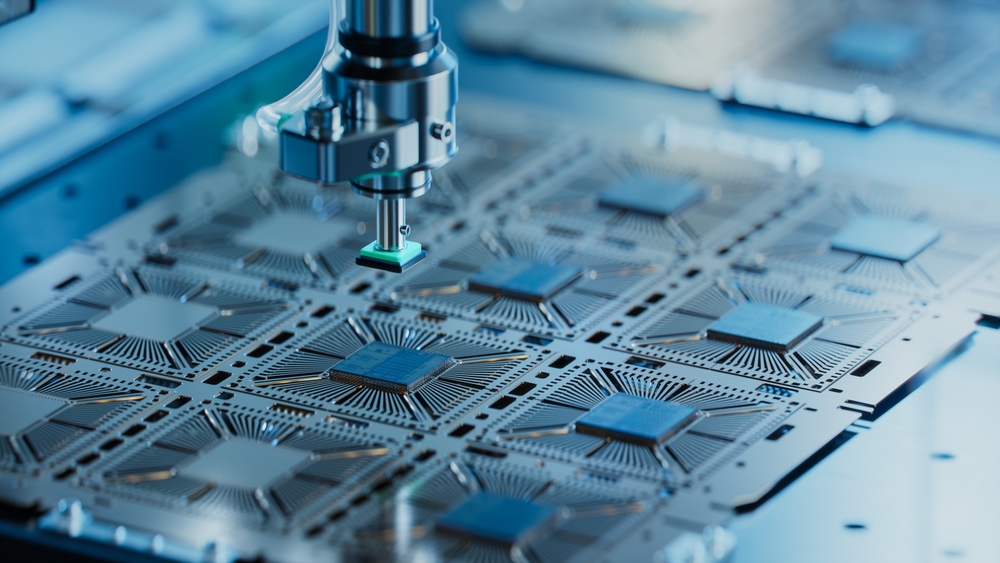

Robotics has been at the heart of electronic manufacturing for decades, but the newest trend is towards collaborative robots (or ‘cobots’) that work alongside human operatives to boost the quality, productivity and complexity of the manufacturing process while retaining flexibility, knowledge, judgement and oversight by people.

Environmental Initiatives

Sustainable manufacturing processes are becoming increasingly desired by consumers and a matter of long-term planning and economics by manufacturers. There is a focus on using recyclable materials, reducing the use and production of hazardous substances and decreasing energy use throughout the manufacturing processes.

There is also the drive to create a circular economy in the electronics industry, which means designing for longevity, repairability and recyclability.

Summing Up

Bringing all these areas together, these technological advancements are driving the electronics manufacturing industry towards greater efficiency, higher performance, and more sustainable practices. As these innovations continue to evolve, they promise to reshape the future of electronics, offering new possibilities and challenges for manufacturers worldwide.

Keep an eye for more latest news & updates on Verified Zine!